ESE6 – The All Rounder

Endless possibilities

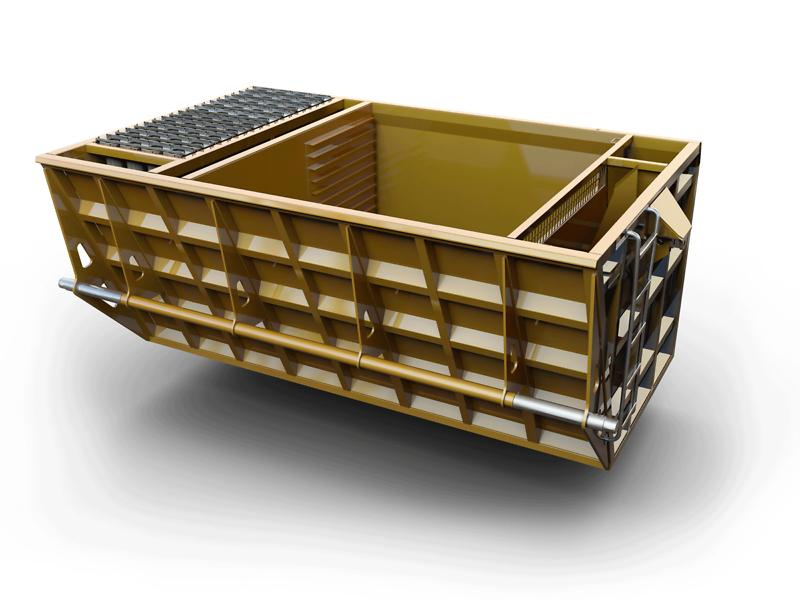

The ESE6 allows for a complete bespoke design approach ranging from container sizes to tipping direction and orientation. The 8m³ container provides more loading volume and therefore the ability to work more effectively. It is perfectly suited to 3 and 4 axle chassis making it our more versatile truck yet. The ESE6 is our most popular model for suction excavation.

The largest container available on this model is the 10m³ which is designed for specialist suction activity which requires a larger material capacity.

Patented separation technology

The newly designed and patented separation chamber provides optimum pre-separation of the material. Long air channels to the micromesh filters cause the stream of air to dry. A constant and effective dust and fume extraction is achieved with the help of the highly effective micromesh filters. The micromesh filter chamber is emptied automatically during the tilting process.

The micromesh filter cleaning system installed as standard ensures optimum cleaning of the micromesh filters. This has a positive effect on the service life of the filters as well as the suction capacity of the complete machine.

The Optimum Working Range

The hydraulic articulated boom has a reach of six metres enabling convenient operation from a safe location. The suction hose is controlled through the remote control handset and can therefore be placed at the suction point.

The fully hydraulic articulated hose carrier is the optimum solution for working at distances between 0 and 6metres. With a swivel range of 180°, the RSP hose carrier was specifically designed with different site conditions in mind.

This allows the machine to work safely where space is limited. The RSP suction hoses were developed especially for high wear. They provide enough flexibility in daily use and with the hose diameter of 250 mm enables effective suction of rough and heavy material.

Monitoring and Control

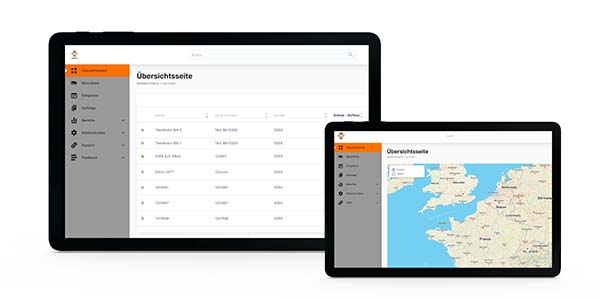

Our modern PLC can be used to adjust 50 parameters and monitor fan speeds, temperatures and hydraulic pressures on the suction excavator.

RSPs PLC continually makes adjustments for optimal operation, notifies the operator of the next service & potential issues.

All fault codes are transmitted to RSPs service team who will either start remote diagnostics with dialogue with the operator or schedule a repair appointment.

The RSP CONNECT system working with the monitoring & control system provides live status updates of your vehicles location & operating condition via the website or the app.

The advantages include efficient scheduling by GPS tracking, reduction in fuel consumption by monitoring both vehicle & fan speeds, and even theft protection or machine misuse.

Proven Technology

For more than 25 years, our proven technology offers our customers the best solutions for daily use. You can completely configure different models according to your intended application. The ESE 6 RD 8000 offers the perfect combination. The 3-axle chassis of all common manufacturers can be used as a basis for this basic structure. Single and double fans can be installed, making possible suction distances of up to 120m depending on the material. The combination of high suction capacity and compact dimensions make the model an all-rounder for daily use on the construction site.

The tasks encountered can be easily accomplished thanks to the a 6.10-m-long articulated hose carrier and a collecting tank of up to 8 m³. Optional pressure or high pressure water systems complete the options on the ESE 6 RD 8000.

Variants

ESE 6 RT 10000

Fan

Container

Compressor

Hose carrier

ESE 6 RD 8000

Fan

Container

Compressor

Hose carrier

ESE 6 RD 6000

Fan

Container

Compressor

Hose carrier